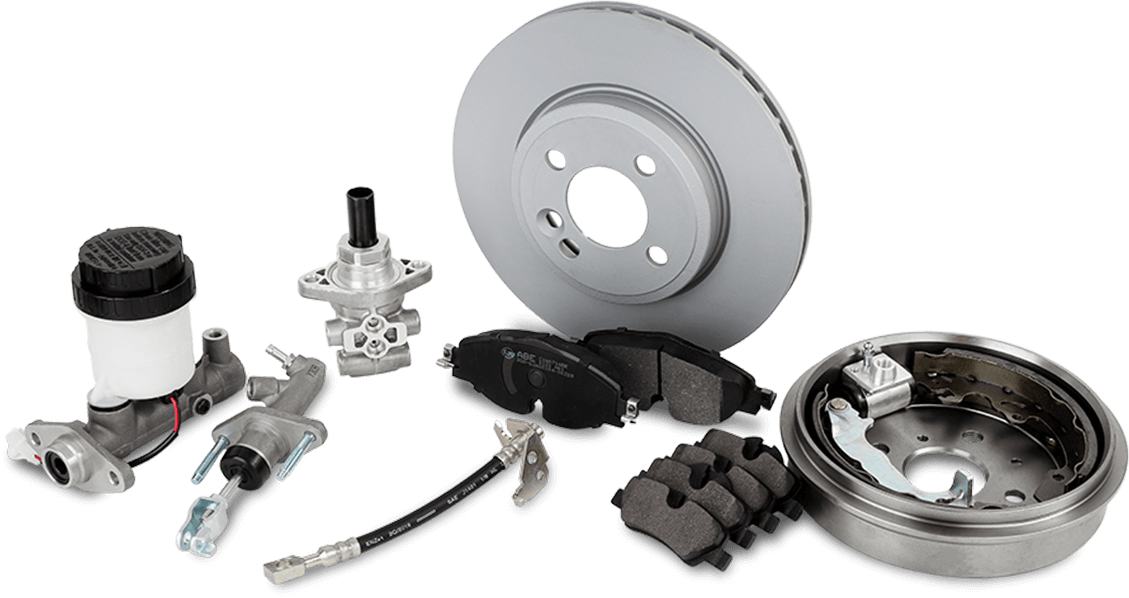

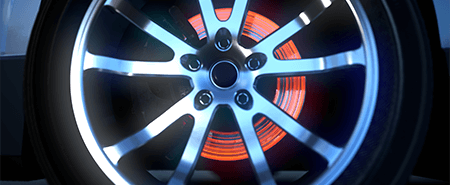

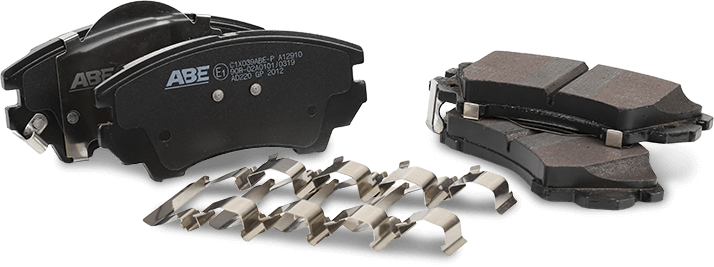

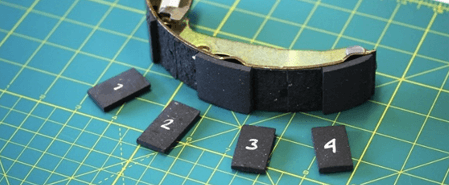

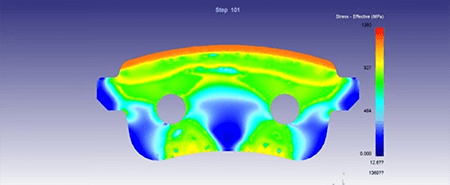

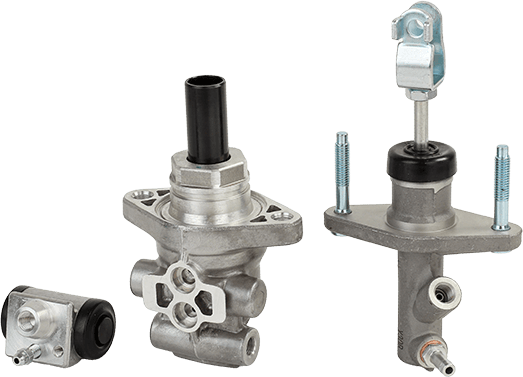

The brake system is one of the most important components of every vehicle. Its efficiency and reliability largely determine the safety of the driver and passengers. Building the ABE offer, we always make sure that products supplied to the market meet all the most rigorous standards. Starting from the stages of design and implementation, through all production processes, we take care of the highest quality in every detail, and thanks to the supervision of professional laboratories, we guarantee quality control of all elements at many levels in order to deliver a final product which is tested, safe and repeatable. Each part of the entire ABE range is a guarantee of quality and reliability.

Choose safely and responsibly! Check why ABE products are worth choosing.